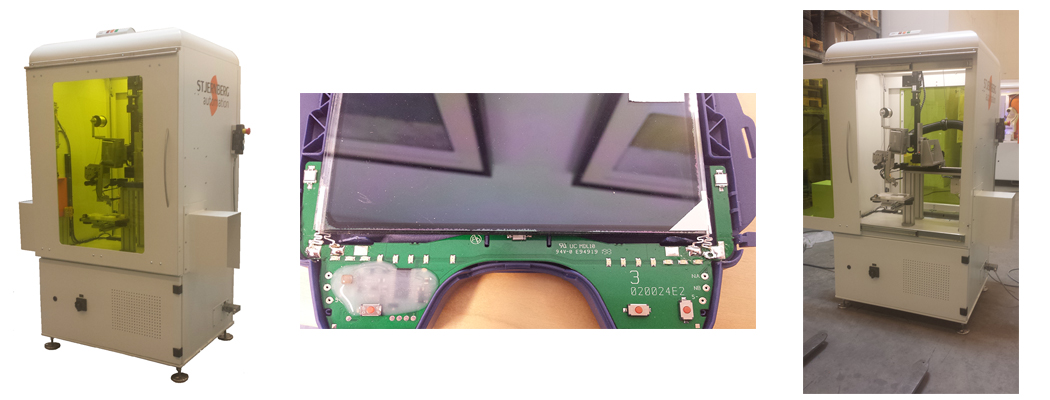

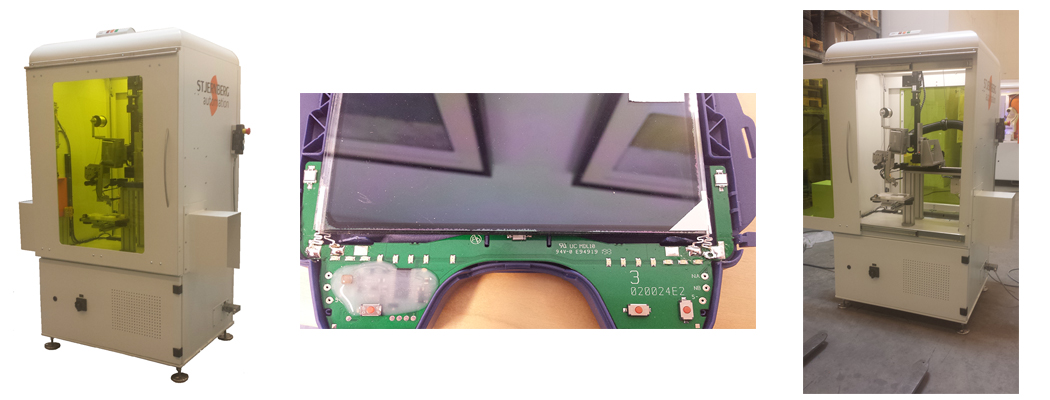

Precision soldering platform for circuit board and electronic components (micromachining)

Background

The client is a globally renowned manufacturer with more than 55,000 products in the industrial, healthcare, and consumer products sectors with annual sales of more than $32 billion.

Demand

In the final assembly, the welding process between the glass unit and the PCB is automated.

? Integration with existing production lines

? Connected with existing control systems

? Maximum processing cycle time does not exceed 15 seconds

Advantages

? Ensure optimal soldering results during closed loop machining

? Plug and play

All electronics integrated in the base frame

? 4-point welding cycle time controlled at 10-14 seconds

Status

? Delivered on time in 2015

? Meets cycle time requirements

? Normal operating rate >97%